It occurred to me that Nigel probably has one of the most interesting voluntary jobs going. And having started doing it shortly after a huge refurbishment in the church tower in 1978, an impressive 40+ year tenure at doing it too.

He is probably the longest serving steeple keeper in the history of the village!

We find ourselves in a bubble (being as Nigel is also my dad) for Lockdown 2.0 and I realise that I am in a unique position to be able to not only interview him about what he does but also to visit and climb the bell tower with him to see the church tower, its clock and its bells first hand.

Over the years it has been observed by some that Nigel is peculiarly interested in making sure that the church clock tells the right time. The village benefits from a very accurate church clock and locals frequently use this clock as a method of checking the correct time on their own time pieces. The clock is rarely more than a few seconds astray … and more often than not it is exactly right.

Keeping time

It might seem like a straightforward task – to manage the relationship between the clock, its time, and the bell that sounds on the hour but, as I discovered, a fair amount of dedication is needed for these things to happen smoothly …

Two days ago the clock was about 30 seconds out. Dad had visited the tower to add a couple of washers to the pendulum to correct it. Later that evening we went outside and listened to the bell chime over the sound of traffic at 6pm. It was still not quite right. Time being of particular interest and importance for the forthcoming Remembrance Sunday. (He is currently going to the tower about twice a week in the name of time keeping due to the malfunction of the bespoke automatic clock time keeper in the tower)

Another visit to the tower was needed to make another adjustment to the church clock and this time I jumped at the opportunity to go with him!

Climbing the tower

It was a beautiful sunny afternoon as we approached the small door to the tower, hidden at the rear of the church and currently surrounded by scaffolding. The church tower is in the process of having all the lead on it removed, in order to melt it down and re-shape it and return it to the tower. It is a huge undertaking and worthy of a blog post in its own right.

The steps to the clock and the bells beyond are narrow stone spiral steps. There are 106 steps to the top. 39 steps to get to the ringing chamber, another 29 to get to the clock chamber, and another 13 odd to get to the bell chamber. And if you’re lucky enough to have access another 26 to the flat roof of the steeple base.

The self winding clock

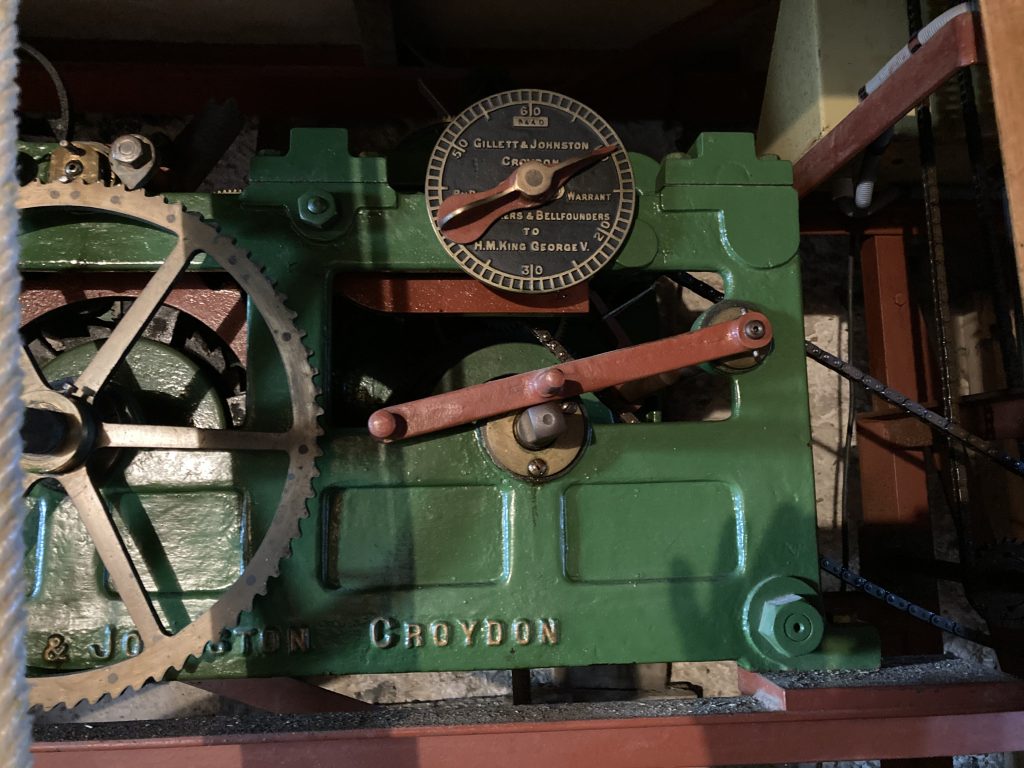

The earliest church clock predates church wardens accounts for this church which start in 1633. There have been four clocks at the church. The current clock was installed in 1931 when the cost of heavy repairs to the old clock (which was installed in 1848) compared unfavourably to the cost of a new clock from Gillett and Johnson of Croydon.

The present clock is a fine example of its type by the leading maker of the time. Until 1978 it sat alone on its wooden horse surrounded by autographs of a century of clock winders. Now it is no longer necessary for the clock to be wound up twice a week as it had a self winding mechanism installed as part of the refurbishment work.

Having to step over a huge pile of lead on the way into the clock chamber which had been removed by the workmen and was making its way down to the ground for melting down. The clock chamber is an amazing room.

Dad explained to me “these weights here are the weights that wind the clock up. They go down, and down – and then, when they reach a certain stage then they wind themselves up again. They are self winding weights. There are some at each side of the clock mechanism.”

Dad put a washer on the pendulum; “We will have to wait until the next chime to see if the washer has done its job.”

Climbing on up to the bell chamber...

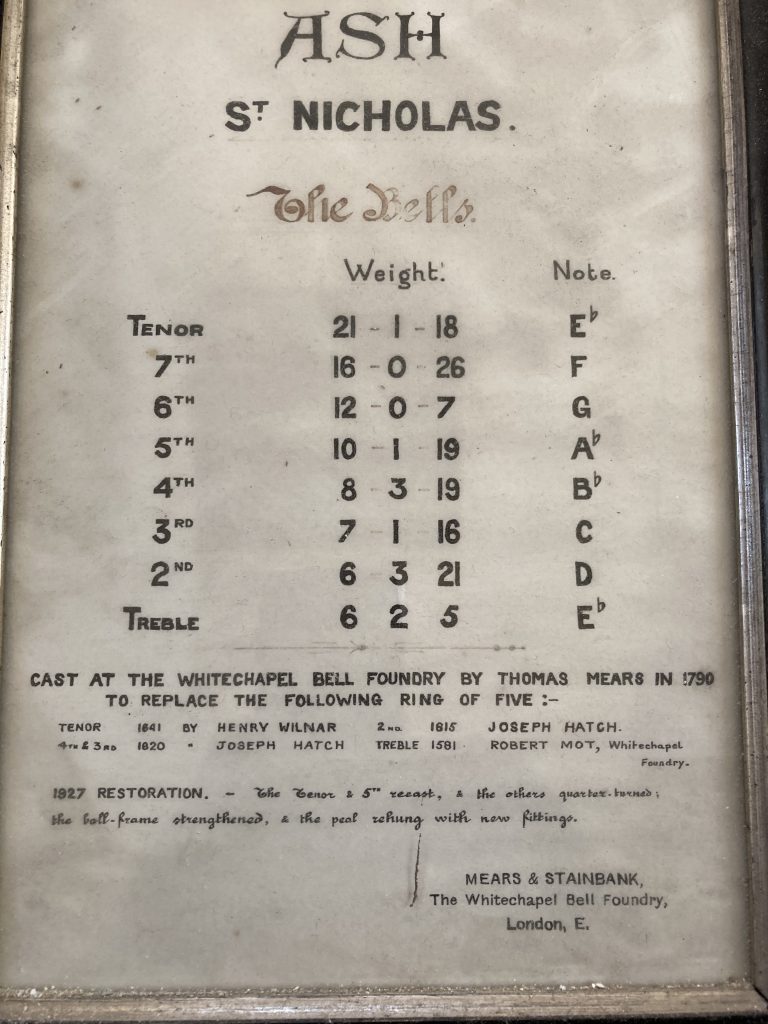

The earliest record of bells in the church is in the year 1496. In the eighteenth century there were five bells in the church tower. The original five bells were installed between 1581 and 1641. These bells were replaced by eight bells which were cast in Whitechapel Bell Foundry by Thomas Mears in 1790.

There is a statement on the wall that gives information about the eight Whitechapel Bell Foundry bells, the notes that they make when rung and their weights.

The statement does not make mention of the fact that, until 1978, the bells cast by Thomas Mears, whilst tuneful, were also very heavy. The combined effect of the weight of the bells, the height of the tower and the design of the frame meant that prior to 1978 the steeple structure moved alarmingly as the bells were rung.

A decision was made to replace the wooden bell frame with a cast iron frame and to increase the stability of the tower by lowering the bells a few feet… and that, at the same time, if the new frame was designed to contain a total of 10 bells it might be possible to add two lighter bells, easier for beginners to learn on.

Therefore, in 1978 the additional two smallest bells were added courtesy of Dr Cave and Mr Foat making a set of 10 bells. At the same time, the original eight bells were taken down to be re-tuned and re-hung on the new frame by John Taylor and Co and to allow the two new bells to be rung as part of the same ‘family’ of bells.

It is most unusual to have ten bells in a church tower

Most churches will have no more than six or eight. In less social distanced times, Campanologists from around the country make special trips to visit this tower to ring these ten bells.

These are strange times

Normally on a Remembrance Sunday a service would be held at the War Memorial in the village and the bell would ring to mark the time at 11 o’clock. This year there is no service being held at the War Memorial in the village so a single bell is being used to mark the 2 minutes silence instead. And it falls to Dad to ring it.

The bells remember

Dad rings a solitary bell for Remembrance Sunday.

And pauses at 11am for the clock to strike and then mark a 2 minute silence.

And then rings again to mark the end of silence.

A note about the Whitechapel Bell Foundry

The bells are interesting in that they were created by Thomas Mears in 1790 at Whitechapel Bell Foundry. The Bell Foundry is the subject of a bitter dispute between an American company who wants to turn the site into a boutique hotel and the British arts scene who passionately want to preserve this historic site and important social history.

You can read more about the campaign to save the Whitechapel Bell Foundry here, and sign a petition to register your support here.

(Do not try typing Whitechapel Bell Foundry into Google as you will come across a page owned by the developers which has been made to look like it is part of the campaign to save the Foundry and which is totally misleading).

all photographs, recordings and videos copyright wewalktogether.uk

Tremendously interesting piece – thank you!

I am so pleased you enjoyed it!

I enjoyed reading your post especially about the Whitechapel Bell Foundry which we always used to drive past on trips up to London. On Remembrance Weekend last year I was campaigning outside the Whitechapel Bell Foundry ringing a bell in the pouring rain. The protest made it on to the ITV London Evening News and in the newspaper.

I absolutely loved that @tisburylicious – not just because it’s so very ‘dad’ to shhhh you whilst waiting for the clock to strike 🤣 & his general obsession with the exactness of that clock for our entire lives, but because I learnt so much I didn’t know (& am astonished not to know by now!). I have also signed & subscribed to the petition for the Whitechapel Bell Foundry. Keep em coming – highlight of my Sunday’s now! X

Glad you’re enjoying them!! Xx

Thank you Tisburylicious! Love your post. So interesting! Thank you for sharing those personal moments.

Anne

So where does the energy come from to wind the self-winding clock?

The weight is moved by electricity.

Brilliant post Sally. I’d have never guessed your dad was custodian of the bells and clock.

What a brilliant blog, didn’t know that the process was so involved